How mechanics and medicine help us live better

Orthopedic surgery for the spine with the use of spine products

As it often happens when speaking about orthopedic surgery, mechanics comes to the aid of medicine. In fact, the human skeleton plays a fundamental role in every movement, in addition to support the weight of the body. Like any mechanical support and movement structure, it is subject to wear.

For this reason, there are various surgical techniques that help us when some parts of our skeleton are no longer able to do their job optimally, causing us pain.

In this article, we would like to talk about a very important part of the skeleton for our upright position: the spine.

Spine products for corrective spine surgery

The spine products are those products that, alone or in combination, are used in spine surgery to solve various pathologies. There are also cases where spine products are used for corrective spine surgery.

Regarding the pathologies of the spinal column to which we are subject as human being, their appearance is due to a main phenomenon that is linked to the evolutionary process of our species: the upright position.

The transition from the four-legged to the standing position caused the whole body weight to shift onto the back. The strong stress to which the spine is subjected often causes wear on the vertebrae.

Posture and work activities can significantly increase this problem which, in any case, afflicts a large part of the population in a more or less serious way.

Spine products: they patologies

This shift in weight has caused different pathologies related to our spine. There are various ways to treat these pathologies before arriving at surgery and spine products.

A first weapon is provided by pharmacological treatments, then it is possible to use physiatric treatments. These first two defenses generally never solve the problem in depth, but they help to postpone the recourse to surgical operations as much as possible.

When all of these approaches fail to reduce pain, we move on to product spine. In recent years, the most important surgery tecnique related to bone degeneration of the vertebrae is the minimally invasive.

Minimally invasive surgery with spine products

The spine products used for this kind of surgical technique are not very different from the classics also used for spine surgery, but these few differences allow the patient to have a very limited aesthetic impact of the surgery and an equally limited hospital stay.

Recovery times, using the minimally invasive technique, are also very fast: one or two months at the most.

Later we will go through the spine products for the minimally invasive technique, let’s start now with the standard spine products.

Standard spine products

The most commonly used spine products are spinal spacers and peduncolar screws.

Polyaxial screw, like the one in the image, are usually used in classical spine surgery. The possibility of tilting the upper part, called tulip, allows the surgeon to find the position in which to insert the bar into the tulip more easily

Peduncolar screws, like the one in the image, are an alternative to polyaxial ones. They are simpler from a mechanical point of view. The choice of the most suitable spine product is always linked to the pathology to be treated and the surgeon’s preferences.

When the vertebrae to be treated are the cervical ones, it is also possible to use a spine product like the one on the side. It is composed of a titanium plate and 4 screws, also in titanium. Mechanically it solves the problem in the same way, fixing and locking 2 adjacent vertebrae.

When the spine products are the pedicular screws (polyaxial or not), the vertebrae are locked using a connecting bar. These bars, like all other components, are made of titanium (1). This bar will be fixed inside the tulips and will mechanically block the movement of the adjacent vertebrae.

(1) In recent years, new schools of thought have brought forward the theory that a mechanical block of the vertebrae with titanium spine products is not the optimal solution for the healing of patients. This is because a rigid mechanical fixation shifts the problem to the still mobile neighboring vertebrae. For this reason, the titanium connecting bars are, in some cases, replaced with CFR Peek bars. This plastic material reinforced with carbon fibers allows the vertebrae a minimum play between them. This micro-mobility, given by these particular spine products, appears to be a better solution for patient healing. However, the use of one or the other method remains at the discretion of the surgeon who has a clear understanding of the patient’s pathology and how to solve his problem

Spine products for minimally invasive

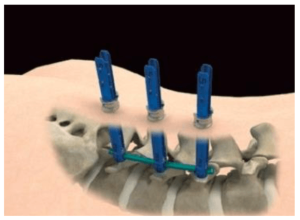

Polyaxial screws used in minimally invasive surgery do not differ much from standard surgery. The biggest difference is in the tulip. The latter, as you can see from the image, is very long compared to one used in standard spine products.

This length, which at first sight seems to be excessive, is deliberately used as an access point for the insertion phase of the junction bars. As you can see from the image below, these long tubulars protrude from the patient during the operation, becoming an advantage for the surgeon when positioning the bars. The thing to note is that the cuts for this kind of operation are limited to the size of the spine products. Small incisions which are not very visible, once the operation is finished.

This type of product spines is much more expensive in terms of production than the standard ones. This is due not only to a matter of more material used but, above all, for the tolerances involved.

It should not be underestimated that, at the end of the operation, the surgeon must remove the excess parts of the tulips. Considering the titanium material, this removal would not be easy if these spine products would not be projected with a programmed breaking .This design and construction aimed at breaking without leaving sharp burrs or pieces of metal inside the body is the greatest difficulty in making these implantable devices. Despite the difficulties, this seems to be the way for all producers, also because the health and well-being of patients is always in first place for every company that produces spine products.

For this reason, the use of minimally invasive operations will become increasingly greater in the future. Not just for the spine. For more than ten years, our company has been collaborating with the most important companies producing spine products as a subcontractor. We can therefore boast a great experience in this field of surgery.

For further information and to discover more about our company: https://rebrand.ly/LegheLeggereSEO