Before speaking about orthopedic plates (orthopedic plates and screws), it is necessary to make an introductory hat on the bone tissue and its composition.

Bone tissue: composition and features for orthopedic plates

Bone tissue is a specialized form of connective tissue. Its composition is made up of living cells and a mineralized intercellular substance, called bone matrix. The latter gives the bone stiffness and mechanical strength, this is because the two components of which it is composed are organic and inorganic in nature. The organic part is a tenacious and yielding component while the inorganic one is rigid and brittle.

Orthopedic plates: composition and features of bone tissue

This composition gives the bones these characteristics:

- stiffness

- toughness

The stifness allows the bones to resist excessive deformation, while the toughness gives the ability to absorb and dissipate energy in shocks (eg during locomotion or in traumatic events) so that the energy transmitted to the most vulnerable organs is minimal.

Bone tissue is mechanically very strong and, at the same time, relatively light. This optimal strength / weight compromise depends on its internal conformation.

Orthopedic plates: variants of bone tissue

n fact, there are two variants of bone tissue, cortical or compact bone and spongy or trabecular bone.The cortical bone is dense, resistant and mechanically rigid; the spongy one, on the contrary, is not very dense and does not guarantee sufficient mechanical resistance by itself. This characteristic of the bones gives them an important resistance to external forces. Despite this, even the most resistant bones of our body can fail, if subjected to major shocks or traumatic events. When we face with a fracture of the long bones, usually, a conservative approach is used which involves immobilization using a cast bandage.

Orthopedic plates: implantable mechanical devices

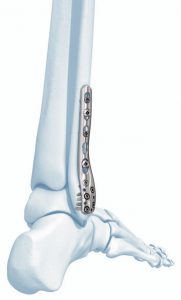

However, in some circumstances it is necessary to stabilize the skeletal segments using mechanical devices such as orthopedic plates, which are applied after surgery: in this case we speak of osteosynthesis. The term orthopedic plates indicate medical devices, defined as implantable, used for the recomposition of fractures of various bones of our skeleton. In this article we would like to consider only orthopedic plates which are defined as long.

Orthopedic Plates (and screws) for long bones

he long bones are the femur, tibia and fibula for the lower limbs; the humerus, the radius and the ulna for the upper limbs.

Types of orthopedic plates

There are various types of orthopedic plates for these bones, you can see some of them below:

Clearly, as you can guess from these few images, each plate is studied, designed and shaped to adapt to the bone for which it is made.

As you can imagine, this determines the realization of many different types of orthopedic plates.

Design of 3D implantable orthopedic plates

The design of these implantable medical devices is a bio-mechanical process. The skilled engineers consider our skeleton as a “machine”, which is why they evaluate all the stresses to which it is subjected. These studies allow to create specific orthopedic plates not only for conformation but also for size and rigidity.All the studies are done with three-dimensional design software.

Orthopedic plates: lab test

However, it is not conceivable to use these devices without first having carried out acceptance tests in the laboratory. For this reason, all implantable medical devices are subjected to long tests in which various cycles of use are simulated to ensure that there are no accidental breakages before the complete recovery of the patient.

Use test on orthopedic plates

The passing of these tests combined with other tests on the use of orthopedic plates on synthetic bones and subsequently in tests on cadavers, allows an implantable medical device to go out on the market.

Titanium orthopedic plates: production of implantable medical devices

In most cases these plates are made of titanium. Other materials are starting to appear on the market, but we will talk about them at the end of the article. The technology to produce these orthopedic plates varies greatly depending on the shape and production volumes. Usually, when volumes are not excessive, the 5-axis machining center is the ideal compromise to produce most of these orthopedic plates. The real skill of the manufacturers, in addition to a great experience in titanium processing, lies in positioning the plates on the machine in order to minimize the positioning. The ideal solution would be a single positioning to carry out all the processes, but this is not always possible for all types of orthopedic plates.After the mechanical processing, the orthopedic plates will have to pass the dimensional tests and then embark on a long journey between surface finishes, washing, laser marking to trace the production batch, packaging and finally sterilization.

CFR peek orthopedic plates

As mentioned above, in addition to titanium, there is another material in which orthopedic plates for long bones are made. This material is CFR peek. Peek is a plastic-type material with not excellent mechanical characteristics, if taken individually.

With the addition of CFR, an acronym that indicates Carbon Fiber Reinforced (carbon fibers), the mechanical existence of the peek improves considerably.

However, this resistance is not comparable to one of titanium, which is why orthopedic plates made with this material are used only for the long bones of the upper limbs: humerus, radius and ulna.

Below you can see some examples of these orthopedic plates:

The advantages of CFR peek orthopedic plates

The advantages of using these orthopedic CFR Peek plates are various. The first is radio transparency. This peculiarity can be very useful for the surgeon, after the operation, to verify bone healing. In fact, it is not possible to have this visibility “through” the plate with metallic materials.A second advantage, for which these orthopedic plates can be considered a valid alternative to metal ones, is that they are not subjected to the phenomenon of the so-called “cold-fusion”. This problem, which is widely known in the field of orthopedic surgery, is very often a problem for surgeons. In fact, due to this phenomenon, screws and metal plates tend to join as if they were fused together, making it very difficult to remove from the patient after healing.Third advantage, the angulation of the fixing screws during the operation. As you can see in the image, surgeons have wide range of decisions, during the operation, to choose the right angle to position the screws.

As you can see in the image, surgeons have wide range of decisions, during the operation, to choose the right angle to position the screws.

Injection molding production for CFR peek orthopedic plates

These orthopedic plates are made with very different technologies than those in titanium. The most important technology is injection molding. Our company is the only one in Europe to have both technologies to produce orthopedic plates for long bones (and more).

For further information and to discover more about our company: https://rebrand.ly/LegheLeggereSEO