Before speaking about the dental implant finishings, let’s try to understand how and when dental implants were born.

History of dental implants

Their origin is not recent, as one might think. In fact, man has been trying to replace any fallen teeth with tools that would make us smile for millennia.Some archaeological finds in the Viterbo area – dating back to the fifth century BC – show that even then man was striving to solve the problem. In this specific case, it was found a gold plate inserted in the premolar and molar area, in order to support any artificial teeth.All these finds had the same purpose: to replace fallen teeth. Since then these attempts have never stopped, reaching the point of achieving something very similar to what we know today. In particulary in 1934, the first porcelain endosseous screws was inserted, to anchor fixed prostheses.In addition to porcelain, different materials had been tested in those years, especially a chromium-cobalt-molybdenum alloy.

Dental implants: the revolution of the ‘80s

Despite all these attempts, it is necessary to wait until the mid-1980s to be able to speak about modern implantology.

Let’s speak now about the topic of the article, the finishings of dental implants.

The credit goes to the Swedish Branemark, and to the new “implant doctrine” that he conceived: osseointegration.The first assumption is: the implant must necessarily osseointegrate with the surrounding bone in the best possible way, in order to work perfectly. To do this, several attempts have been made over the years, using always the same material, titanium, and working only on the threads and surface finishings. Experiments of thread geometries and finishing processes of different dental implants have taken place over the last thirty years, in order to give patients the best product according to the state of the art at that time.

The dental implant finishing are mainly two

The first characterizes the implants in the upper part, an area that will come in contact with the gum. For this reason, the finishings of the dental implants in this area have a very low degree of roughness.

To obtain this degree of roughness, a tumbling process which allows to round the sharp edges and smooth the flat parts of the dental implant is performed.

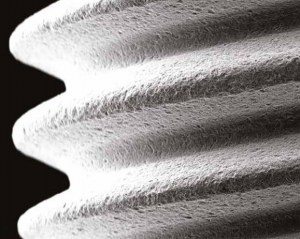

The second, which is used for the finishings of dental implants in the area that will come in contact with the bone, is rougher.

This finishing is achieved with the “corundum shot peening” proces after the tumbling.

In order to avoid damages in the upper part of the implant, the extremity of the implant itself is protected with caps made of rubbery material.

But what is the corundum shot peening finishing? And why is it used as a finishing for dental implants?

This process is mainly a surface cleaning process of metals and it is performed with white corundum grit. This material is characterized by a high purity and absence of contaminants.This finishing is usefule to maks the surfaces of the treated dental implants homogeneous and to improve their resistance to fatigue.After the treatment of dental implants, the appearance of the treated areas is uniform and homogeneous. The process is carried out by means of a stream of air and grit (micro corundum granules). This allows the abrasion of the surface of the piece, whose roughness is adjustable according to the size of the grit used and the pressure of the air stream.

In the last finishing phase of the dental implants, the mordant is placed.

In this process, performed with acids that “attack” the surface of the implant that will come into contact with the bone (the upper part always excluded), the surface is made even more rough.

This allows better osseointegration of the implant.

For further information and to discover more about our company: https://rebrand.ly/LegheLeggereSEO